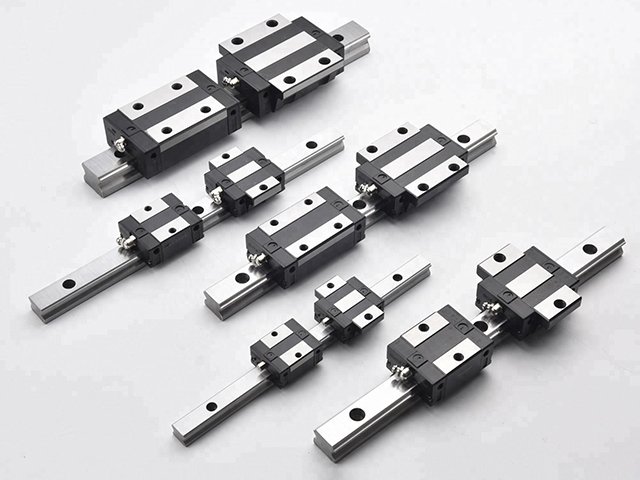

Linear guides can be divided into: roller linear guides, cylindrical linear guides, and ball linear guides, which are used to support and guide moving parts and perform reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides and other types.

1. Definition:

Linear guides, also known as line rails, slide rails, linear guide rails, and linear slide rails, are used in linear reciprocating motion occasions, and can bear a certain torque, and can achieve high-precision linear motion under high load conditions. In the Chinese mainland called linear guide rail, Taiwan is generally called linear guide rail, linear slide rail.

2. Classification:

Divided into square ball linear guide, double-axis roller linear guide, and single-axis linear guide.

3. Function:

The function of the linear guide motion is to support and guide the moving parts and make a reciprocating linear motion in a given direction. According to the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides and other types.

Linear bearings are mainly used in automated machineries, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guides and linear shafts are used together. For example, linear guides are mainly used in mechanical structures with relatively high precision requirements. There is no intermediate medium between the moving elements and fixed elements of linear guides, but rolling steel balls.

4. Application:

①Linear guides are mainly used in automated machineries, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear guides and linear axes are used together.

②The linear guide is mainly used in the mechanical structure with high precision requirements. There is no intermediate medium between the moving element and the fixed element of the linear guide, but rolling steel balls. Because the rolling steel ball is suitable for high-speed movement, small friction coefficient and high sensitivity, it can meet the working requirements of moving parts, such as tool rests of machine tools, carriages, etc. If the force acting on the steel ball is too large, the steel ball will be subjected to preloading for too long, resulting in an increase in the movement resistance of the bracket.